Brackish water Reverse Osmosis (RO) Elements

TFB Series-Brackish Water RO Membranes

Product Description

TFB RO membrane elements are mainly used for brackish water desalination. They provide excellent, stable and consistent membrane performance for industrial water treatment systems. The element operates under low pressure providing a more cost effective alternative for industrial-grade water treatment applications. It has high rejection rate for dissolved salts that are difficult to remove, such as TOC, SiO2, etc., and therefore, applicable to near zero discharge for oil and petrochemical industry waste water treatment and feed water for thermal power plant boilers. These RO membranes are available in 4”and 8” sizes.

Product Highlights

· Stable performance and high rejection rate for organics

· Low operating pressures, high flux and cost saving

· Meet the demand for near zero discharge

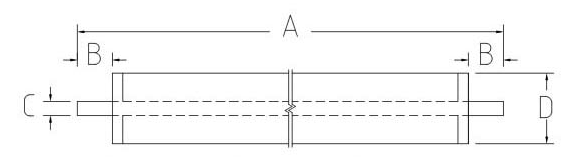

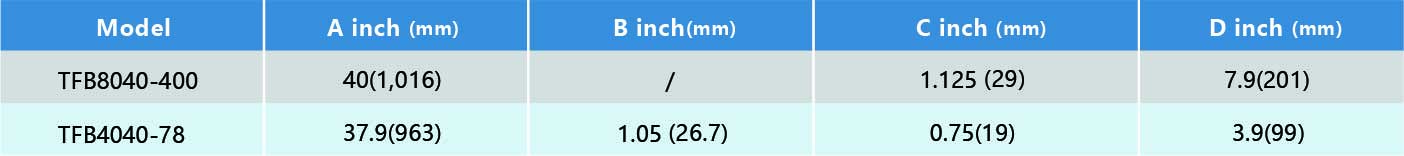

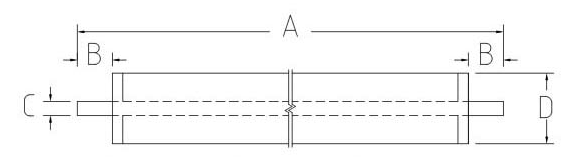

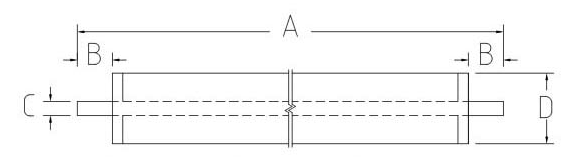

Product Dimensions

Product Specifications

Flux and rejection rate is based on the following standard test conditions: 1.55 MPa (225 psi) feedwater pressure, 77°F (25°C), 2,000 ppm NaCl solution, pH 8, 15% recovery.

Operating and Cleaning Limits

Notes

· Maximum Operating Pressure 41 bar (600 psi)

· Maximum Operating Temperature 45°C (113°F )

· Maximum Element Pressure Drop 1.0 bar (15psi)

· pH Range Continuous Operation 2-11

· pH Range Short-Term Cleaning 1-13

· Maximum Feed SDI(SDI15) 5.0

· Free Chlorine Tolerance < 0.1 ppm

· Permeate flow for individual elements may vary ±15 percent from the value specifed.

· Active membrane area guaranteed ±4%.

· Stabilized salt rejection is generally achieved within 24-48 hours of continuous use; depending uponfeedwater characteristics and operating conditions.

FR Series- Fouling Resistance Brackish Water RO Membranes

Product Description

Transfilm FR series RO membrane elements are highly resistant to organic and microbial contamination, and are used to treat water sources such as paper plants waste water, dyeing waste water and industrial waste water from thermal power plants. The proprietary technology alters the electric-static charges and smoothness of the membrane surface, and enhances the hydrophilicity of the membrane surface. These alternatives greatly reduce the pollutants and

microorganisms attached to the surface layer, therefore it reduces the fouling rate and extends service life. It is capable totackle with poor feed water quality. These RO membranes are available in 4”and 8” sizes.

Product Highlights

· Enhanced fouling resistance

· Suitable for membrane system with poor feed water quality

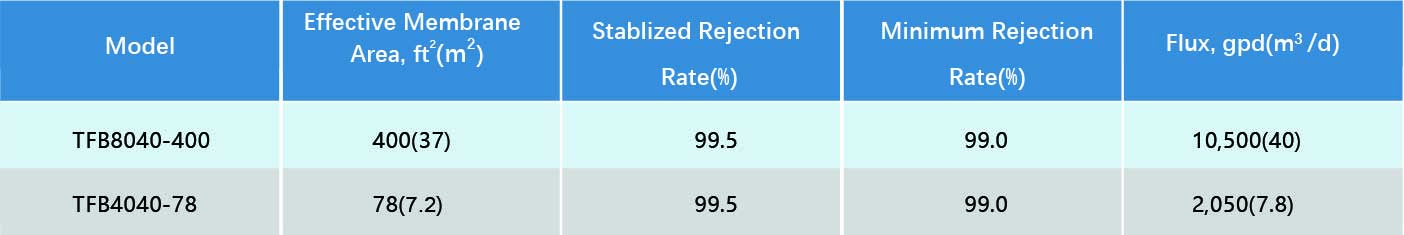

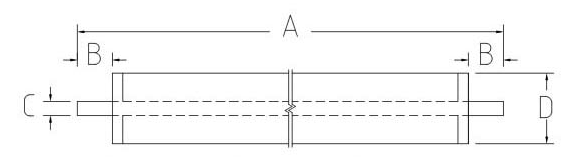

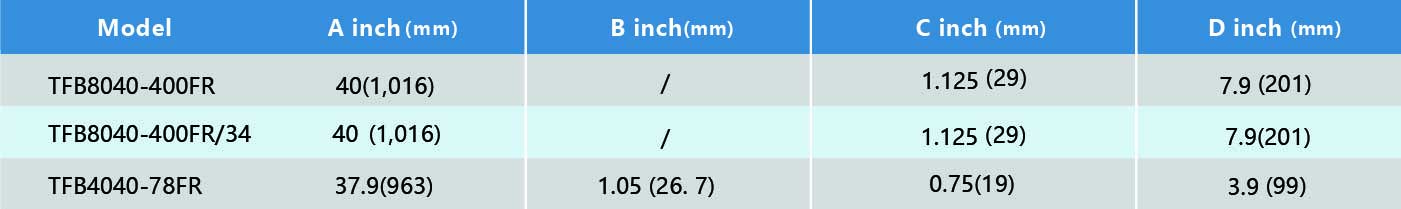

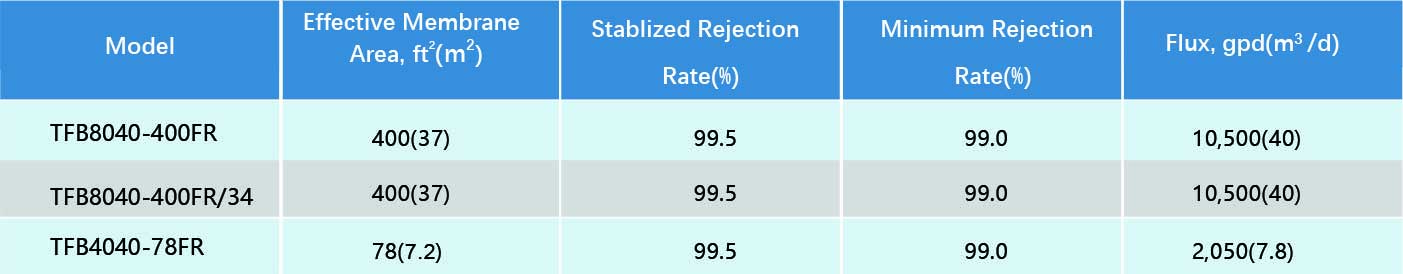

Product Dimensions

Product Specifications

Flux and rejection rate is based on the following standard test conditions: 1.55 MPa (225 psi) pressure, 77°F (25°C), 2,000 ppm NaCl solution and pH 8 for feedwater, and 15% recovery.

Operating and Cleaning Limits

Notes

· Maximum Operating Pressure 41 bar (600 psi)

· Maximum Operating Temperature 45°C (113°F )

· Maximum Element Pressure Drop 1.0 bar (15psi)

· pH Range Continuous Operation 2-11

· pH Range Short-Term Cleaning 1-13

· Maximum Feed SDI(SDI15) 5.0

· Free Chlorine Tolerance < 0.1 ppm

· Permeate flow for individual elements may vary ±15 percent from the value specifed.

· Active membrane area guaranteed ±4%.

· Stabilized salt rejection is generally achieved within 24-48 hours of continuous use; depending uponfeedwater characteristics and operating conditions.

XFR Series-Extra Fouling Resistance RO Membranes

Product Description

Transfilm XFR series RO membranes are manufactured by the optimized formula, reaction conditions and post-treatment.The membrane thin film layer is denser, more hydrophilic, and the membrane surface is smoother. The membrane element is optimized in structure and manufactured with premium material. The membrane can effectively purify feed water with biological and organic pollution. Transfilm XFR series adopts the latest membrane technology enabling

industry’s first-class organism fouling resistance and cleanability. It provides membrane elements with excellent fouling resistance and super durability for the difficult waste water treatment. Transfilm XFR series are available in 8-inch and 4-inch sizes, which are suitable for systems with poor feed water quality.

Product Highlights

· Enhanced fouling resistance

· High performance and durability

· High rejection rate and flux

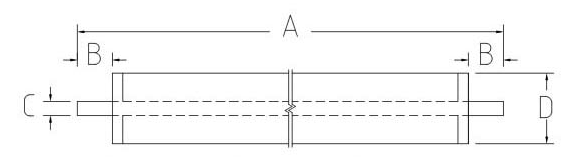

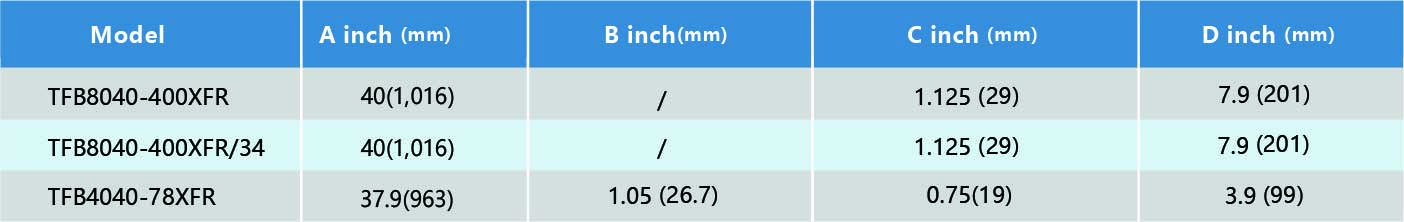

Product Dimensions

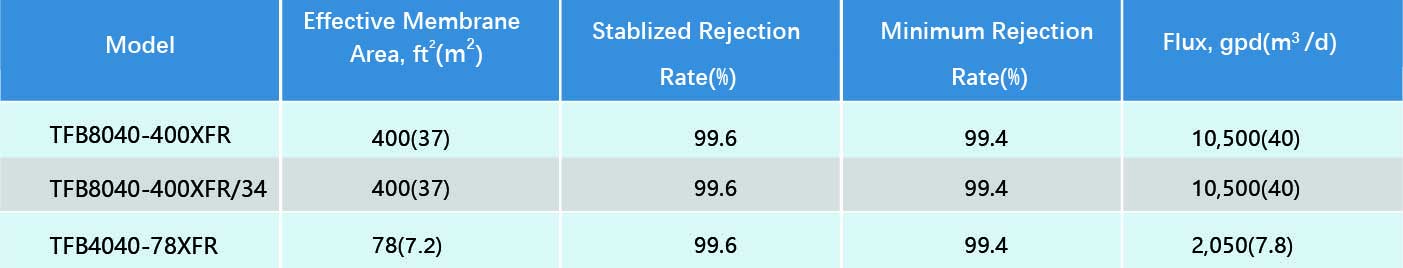

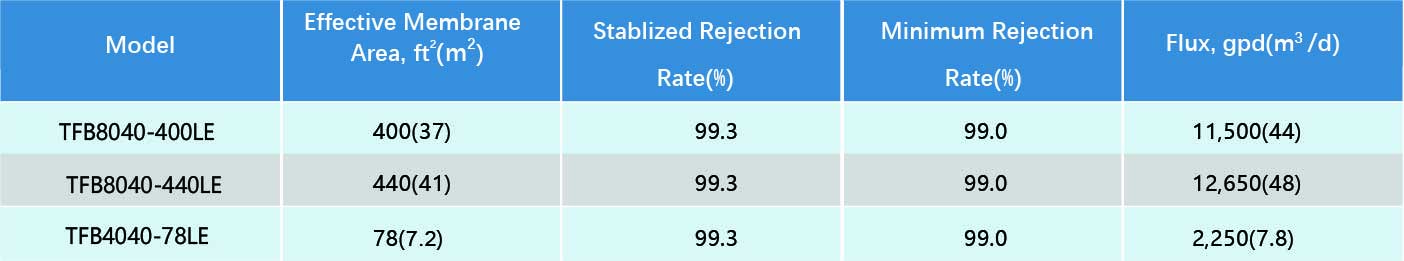

Product Specifications

Flux and rejection rate is based on the following standard test conditions: 1.55 MPa (225 psi) pressure, 77°F (25°C), 2,000 ppm NaCl solution and pH 8 for feedwater, and 15% recovery.

Operating and Cleaning Limits

Notes

· Maximum Operating Pressure 41 bar (600 psi)

· Maximum Operating Temperature 45°C (113°F )

· Maximum Element Pressure Drop 1.0 bar (15psi)

· pH Range Continuous Operation 2-11

· pH Range Short-Term Cleaning 1-13

· Maximum Feed SDI(SDI15) 5.0

· Free Chlorine Tolerance < 0.1 ppm

· Permeate flow for individual elements may vary ±15 percent from the value specifed.

· Active membrane area guaranteed ±4%.

· Stabilized salt rejection is generally achieved within 24-48 hours of continuous use; depending uponfeedwater characteristics and operating conditions.

LE Series- Low Energy Brackish Water RO Membranes

Product Description

Transfilm LE series RO membranes are manufactured by changing the formula and process conditions of the supporting layer and thin film composite layer, therefore the membrane density and properties are altered. Compared with the traditional brackish water RO membrane, it provides 99.3% rejection rate, at a lower operating pressure by 33%. The application of this RO membrane element reduces the RO system’s energy consumption by 1/3, without compromising the product water quality. These RO membranes are available in 4” and 8” sizes.

Product Highlights

· Significantly lower membrane system’s operating pressure and power consumption

· High rejection rate and flux

· Cost-effectiveness of membrane system

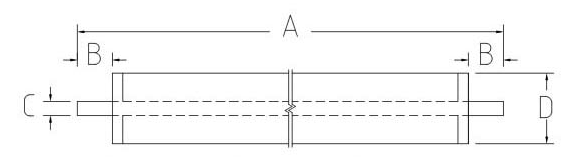

Product Dimensions

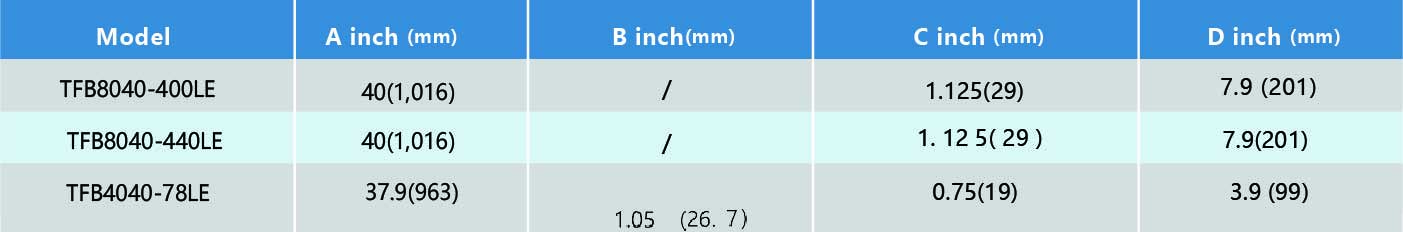

Product Specifications

Flux and rejection rate is based on the following standard test conditions: 1.03 MPa (150 psi) pressure, 77°F (25°C), 2,000 ppm NaCl solution and pH 8 for feedwater, and 15% recovery.

Operating and Cleaning Limits

Notes

· Maximum Operating Pressure 41 bar (600 psi)

· Maximum Operating Temperature 45°C (113°F )

· Maximum Element Pressure Drop 1.0 bar (15psi)

· pH Range Continuous Operation 2-11

· pH Range Short-Term Cleaning 1-13

· Maximum Feed SDI(SDI15) 5.0

· Free Chlorine Tolerance < 0.1 ppm

· Permeate flow for individual elements may vary ±15 percent from the value specifed.

· Active membrane area guaranteed ±4%.

· Stabilized salt rejection is generally achieved within 24-48 hours of continuous use; depending uponfeedwater characteristics and operating conditions.

XLE Series-Extra Low Energy RO Membranes

Product Description

By changing membrane surface and chemical properties, and upgrading the formulation and production conditions for both the supporting layer and thin film composite layer, Transfilm XLE Series RO membrane offer enlarged specific surface area and hydrophilicity to maximize permeate flux rate. It is applicable for municipal waste water treatment, and it is one of the membrane elements with the highest water flux and lowest operating pressure. The total cost of the system with this element is the lowest, therefore it can significantly improve overall operating economy of the membrane system. As the latest RO membrane element with extra-low energy consumption and high performance, its operating pressure is about 1/2 less than regular TFB RO membrane elements, and the rejection rate can reach 99%. These RO membranes are available in 4”and 8” sizes.

Product Highlights

· High flux rate and extra low operating pressure

· Lower power consumption of membrane systems without compromising high rejection rate

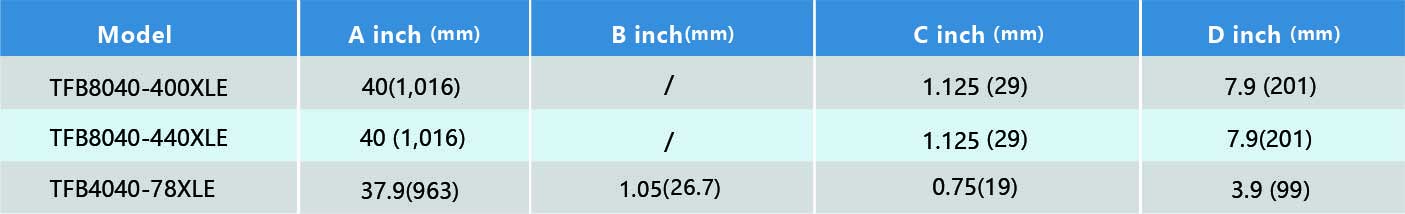

Product Dimensions

Product Specifications

Flux and rejection rate is based on the following standard test conditions: 0.69 MPa (100 psi) pressure, 77°F (25°C), 500 ppm NaCl solution and pH 8 for feedwater, and 15% recovery.

Operating and Cleaning Limits

Notes

· Maximum Operating Pressure 41 bar (600 psi)

· Maximum Operating Temperature 45°C (113°F )

· Maximum Element Pressure Drop 1.0 bar (15psi)

· pH Range Continuous Operation 2-11

· pH Range Short-Term Cleaning 1-13

· Maximum Feed SDI(SDI15) 5.0

· Free Chlorine Tolerance < 0.1 ppm

· Permeate flow for individual elements may vary ±15 percent from the value specifed.

· Active membrane area guaranteed ±4%.

· Stabilized salt rejection is generally achieved within 24-48 hours of continuous use; depending uponfeedwater characteristics and operating conditions.

FRLE Series-Fouling Resistance & Low Energy RO Membranes

Product Description

Transfilm FRLE series RO membrane element has superior fouling resistance and low energy consumption. It is manufactured for treating the feed water with biofouling or organism fouling. Its operating pressure is 30% lower than the regular TFB RO membranes, and its rejection rate can reach up to 99.3%. These RO membranes are available in 4”and 8” sizes.

Product Highlights

· Low power consumption and reduced costs of themembrane system· Superior high fouling resistance and suitable for poor feed water quality

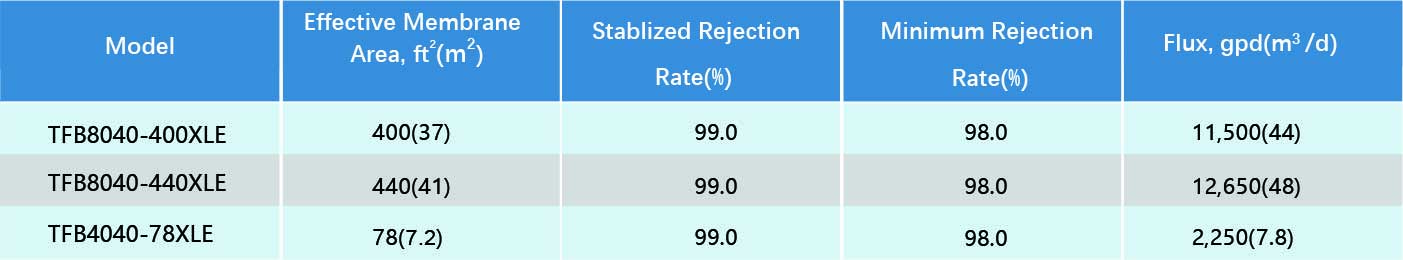

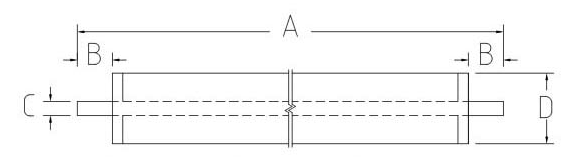

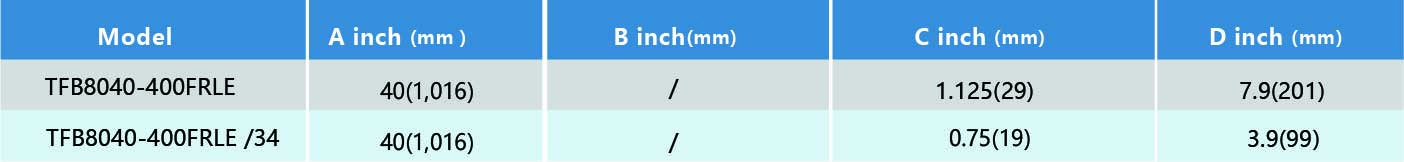

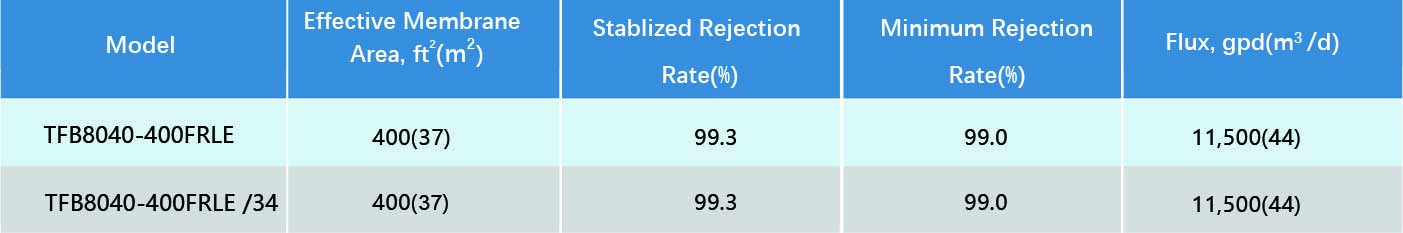

Product Dimensions

Product Specifications

Flux and rejection rate is based on the following standard test conditions: 0.69 MPa (100 psi) pressure, 77°F (25°C), 500 ppm NaCl solution and pH 8 for feedwater, and 15% recovery.

Operating and Cleaning Limits

Notes

· Maximum Operating Pressure 41 bar (600 psi)

· Maximum Operating Temperature 45°C (113°F )

· Maximum Element Pressure Drop 1.0 bar (15psi)

· pH Range Continuous Operation 2-11

· pH Range Short-Term Cleaning 1-13

· Maximum Feed SDI(SDI15) 5.0

· Free Chlorine Tolerance < 0.1 ppm

· Permeate flow for individual elements may vary ±15 percent from the value specifed.

· Active membrane area guaranteed ±4%.

· Stabilized salt rejection is generally achieved within 24-48 hours of continuous use; depending uponfeedwater characteristics and operating conditions.

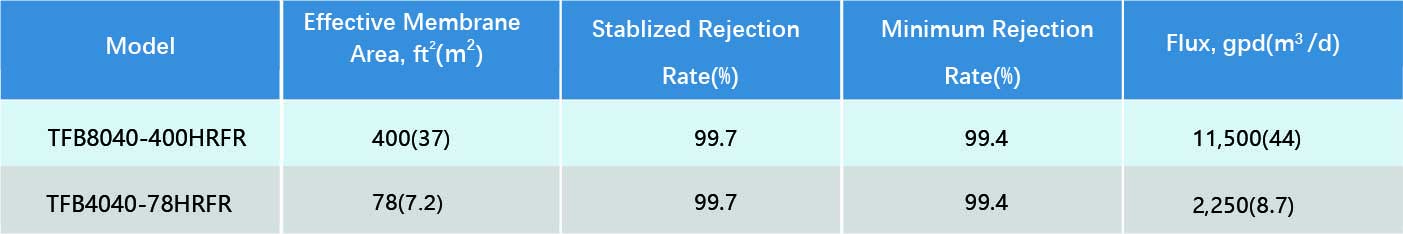

HRFR Series-High Rejection & Fouling Resistance Brackish RO Membranes

Product Description

Transfilm HRFR series RO membrane element is one of the RO membrane elements with a maximum and stable desalination rate at 99.7%. In general industrial and water treatment applications, it only needs one primary RO membrane system to meet the strictest requirements for effluent water quality. With an active area of 400 square feet, it can not only maximize productivity, but also achieve accurate system design and predictable flux. It can meet high water purification

requirements at low cost. These RO membranes are available in 4”and 8” sizes.

Product Highlights

· Ulrta high and stable rejection rate

· Suitable for feed water with high salt content

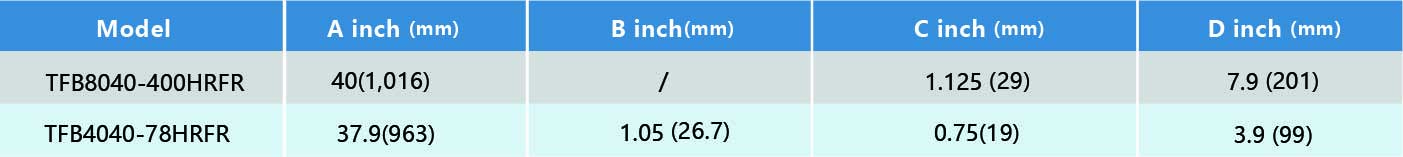

Product Dimensions

Product Specifications

Flux and rejection rate is based on the following standard test conditions: 1.55 MPa (225 psi) pressure, 77°F (25°C), 2000 ppm NaCl solution and pH 8 for feedwater, and 15% recovery.

Operating and Cleaning Limits

Notes

· Maximum Operating Pressure 41 bar (600 psi)

· Maximum Operating Temperature 45°C (113°F )

· Maximum Element Pressure Drop 1.0 bar (15psi)

· pH Range Continuous Operation 2-11

· pH Range Short-Term Cleaning 1-13

· Maximum Feed SDI(SDI15) 5.0

· Free Chlorine Tolerance < 0.1 ppm

· Permeate flow for individual elements may vary ±15 percent from the value specifed.

· Active membrane area guaranteed ±4%.

· Stabilized salt rejection is generally achieved within 24-48 hours of continuous use; depending uponfeedwater characteristics and operating conditions.